Advisory Hotline

0086-519- 86-

Products

Contact Us

Address: No.5, Dongpei Road, Daitou Industrial Park, Liyang City, Jiangsu Province

Telephone: 0086-519-

Fax: 0086-519-

Mobile: +86-

Mailbox: jszxby@loga.cc

Product Display

Classification:

Product Description

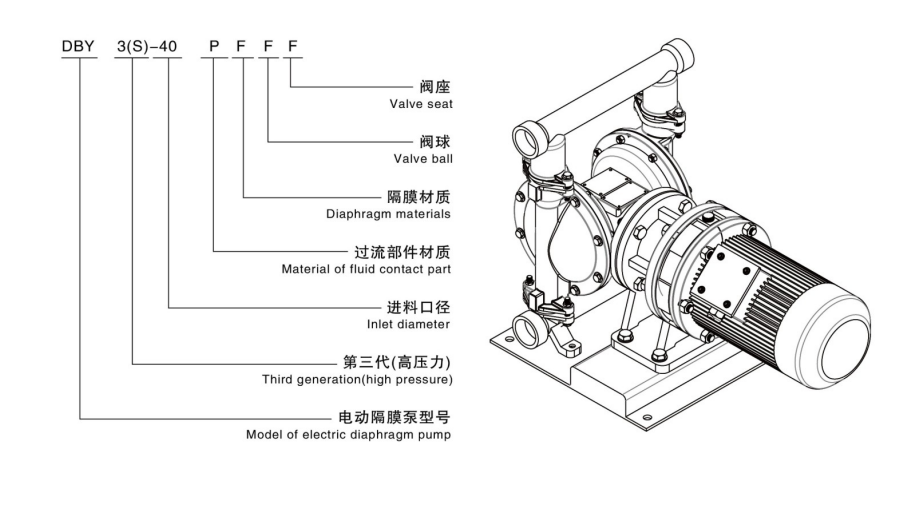

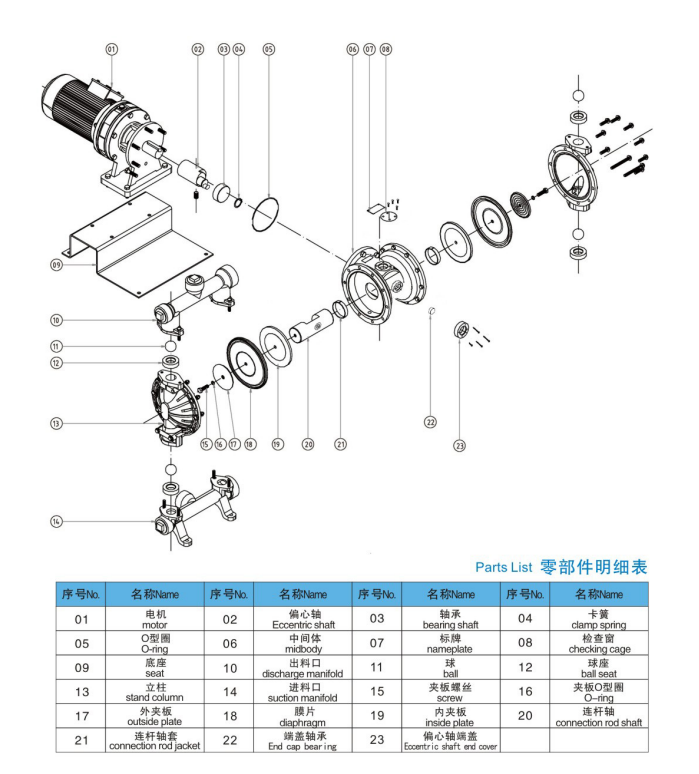

DBY3 electric diaphragm pump is a new type of pump. In recent years, due to breakthrough progress in diaphragm materials, more and more industrialized countries in the world have adopted this type of pump to replace some centrifugal pumps and screw pumps for petrochemical, ceramic, metallurgical and other industries. The product design refers to the prototype of ABEL Company in the United States. The pump is suitable for occasions with low pressure, I .e. outlet pressure ≤ 3kgf/cm2.

Mainly used:

1. All kinds of highly toxic, flammable and volatile liquids.

2. All kinds of strong acid, strong alkali, strong corrosive liquid.

3, can transport higher temperature medium 150 ℃.

4. As the pre-stage pressure feeding device of various filter presses.

5. Hot water recovery and circulation.

6. Oil tanker, oil depot and oil loading and unloading.

7. Pump kimchi jam, mashed potatoes, chocolate, etc.

8. Pump paint, gum, pigment adhesive.

9, all kinds of porcelain glaze slurry cement grouting mortar slurry.

10. All kinds of rubber latex, organic solvent, filler.

11, with a pump for the tanker barge clearance suction silo sewage and residual oil.

12, hops and baking powder slurry, syrup, sugar.

13, pump suction mine, tunnel, tunnel, sewer sewage, sediment.

14. Suction and delivery of various special media.

|

Model |

Maximum flow |

Maximum suction |

Maximum lift |

Motor power |

Maximum particle diameter that can be passed |

|

|

(m³/h) |

(L/min) |

(m) |

(m) |

(KW) |

(mm) |

|

|

DBY3-10/15 |

0.76 |

12.8 |

3 |

40 |

0.55/1450 |

0.5 |

|

DBY3S-10/15 |

0.76 |

12.8 |

3 |

70 |

0.75/1450 |

0.5 |

|

DBY3-20/25 |

1.56 |

26 |

4 |

70 |

0.55/1450 |

2.5 |

|

DBY3S-20/25 |

1.56 |

26 |

4 |

70 |

0.75/1450 |

2.5 |

|

DBY3-32/40/25A |

4.5 |

75 |

4 |

40 |

1.5/1450 |

3.5 |

|

DBY3S-32/40/25A |

4.5 |

75 |

4 |

70 |

2.2/1450 |

3.5 |

|

DBY3-50/65 |

9.72 |

162 |

5 |

40 |

2.2/1450 |

6 |

|

DBY3S-50/65 |

9.72 |

162 |

5 |

70 |

3/1450 |

6 |

|

DBY3-80/100 |

16 |

266 |

5 |

40 |

3/1450 |

8 |

|

DBY3S-80/100 |

16 |

266 |

5 |

70 |

4/1450 |

8 |

|

DBY3-125 |

28.8 |

480 |

5 |

40 |

5.5/1450 |

10 |

|

DBY3S-125 |

28.8 |

480 |

5 |

70 |

7.5/1450 |

10 |

Product Inquiry

Contact Information

Address: No.5, Dongpei Road, Daitou Industrial Park, Liyang City, Jiangsu Province

Telephone: 0086-519-

/

/

Fax: 0519-

Service Hotline: +86-

Mailbox: jszxby@loga.cc

Mobile Website

WeChat QR Code